Pharma Industry

0

+Years

Product Development

0

+Years

Pharma Products

0

+

Exports

0

+Countries

VISION:

To become the most admired Healthcare company by our doctors, patients, pharmacists, distributors, employees, investors, and the communities where we work.

MISSION:

To successfully manufacture and market innovative products with world class quality and to prevent and cure diseases improving the quality of life in millions of patients.

OUR CORE VALUES AND GOALS :

- We believe in Integrity in medicine with great responsibility.

- To create world-class innovative products with highest quality.

- Being humane towards our employees with good work ethics.

- To create business value through customer friendly policies.

- Encourage innovation, creativity and enthusiasm at work place.

- To Implement Safety, Health and Environment Friendly policies.

- To Achieve Excellence in Ayurveda and Healthcare Services.

- To serve mankind by providing affordable quality healthcare for all.

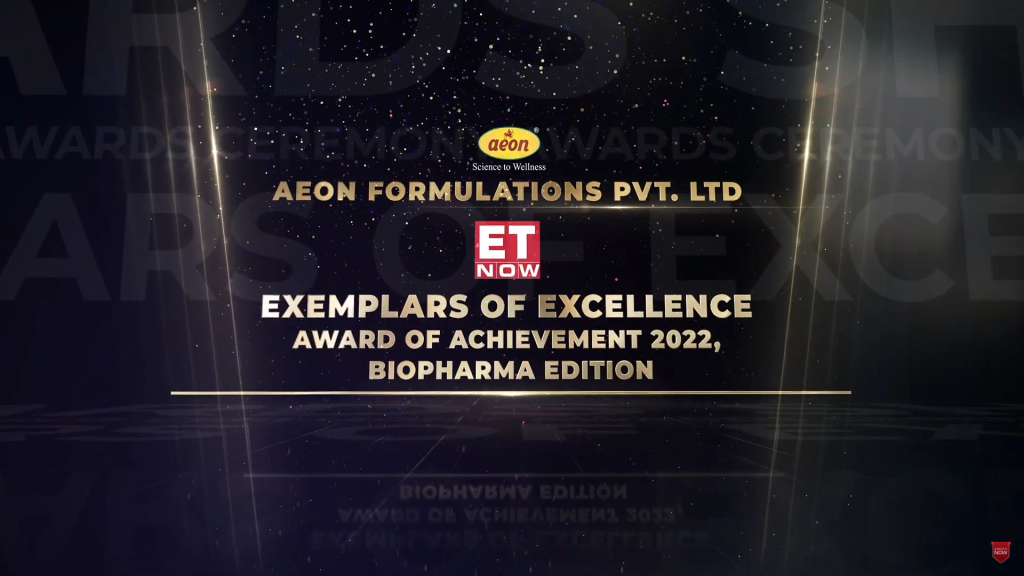

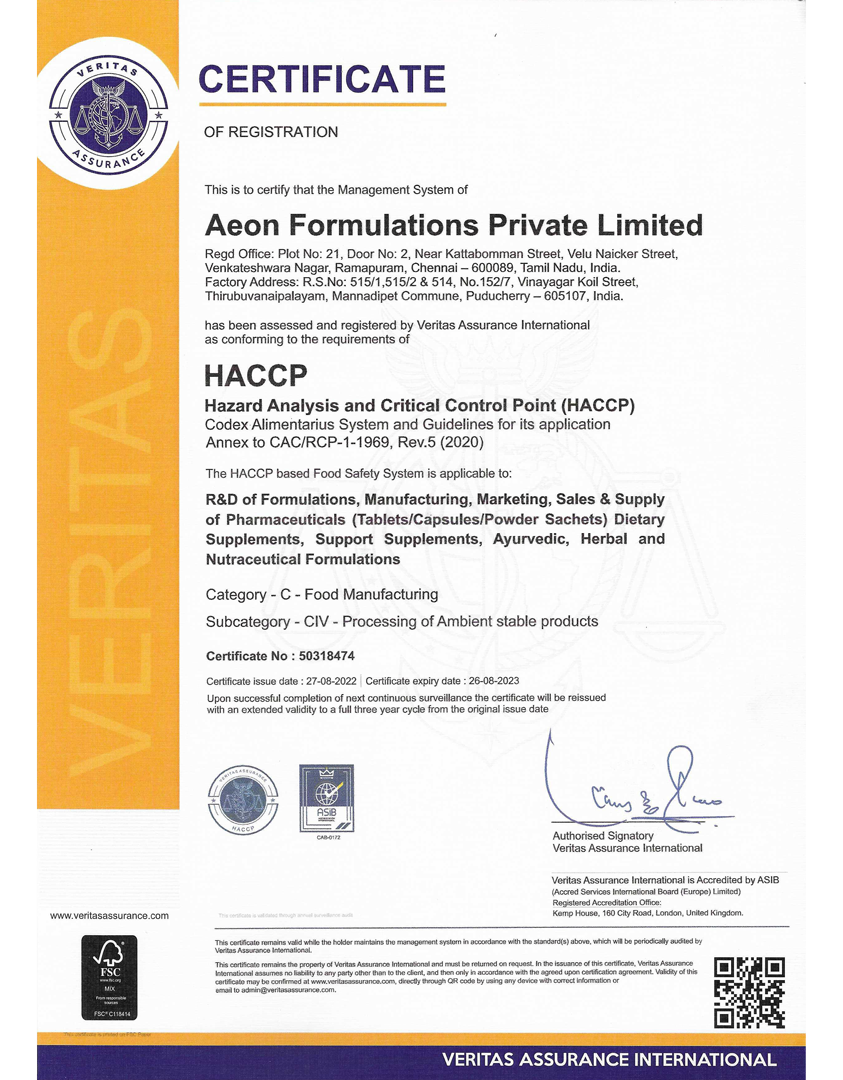

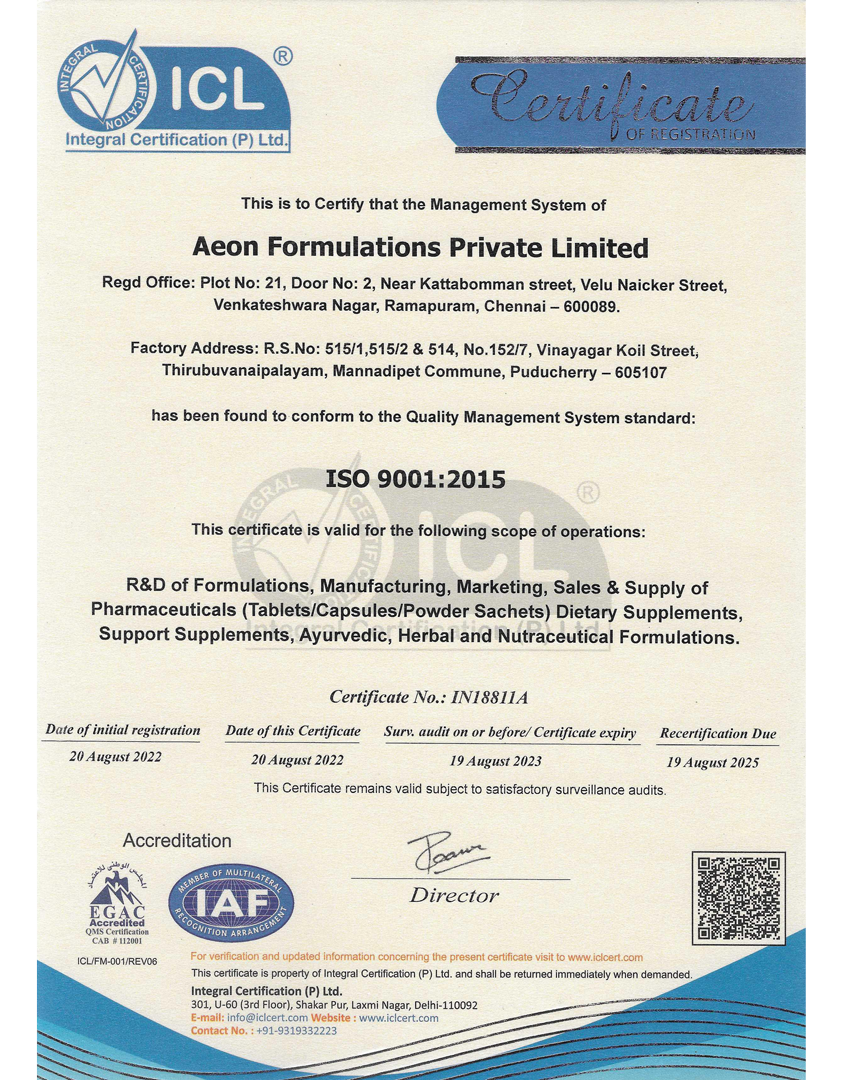

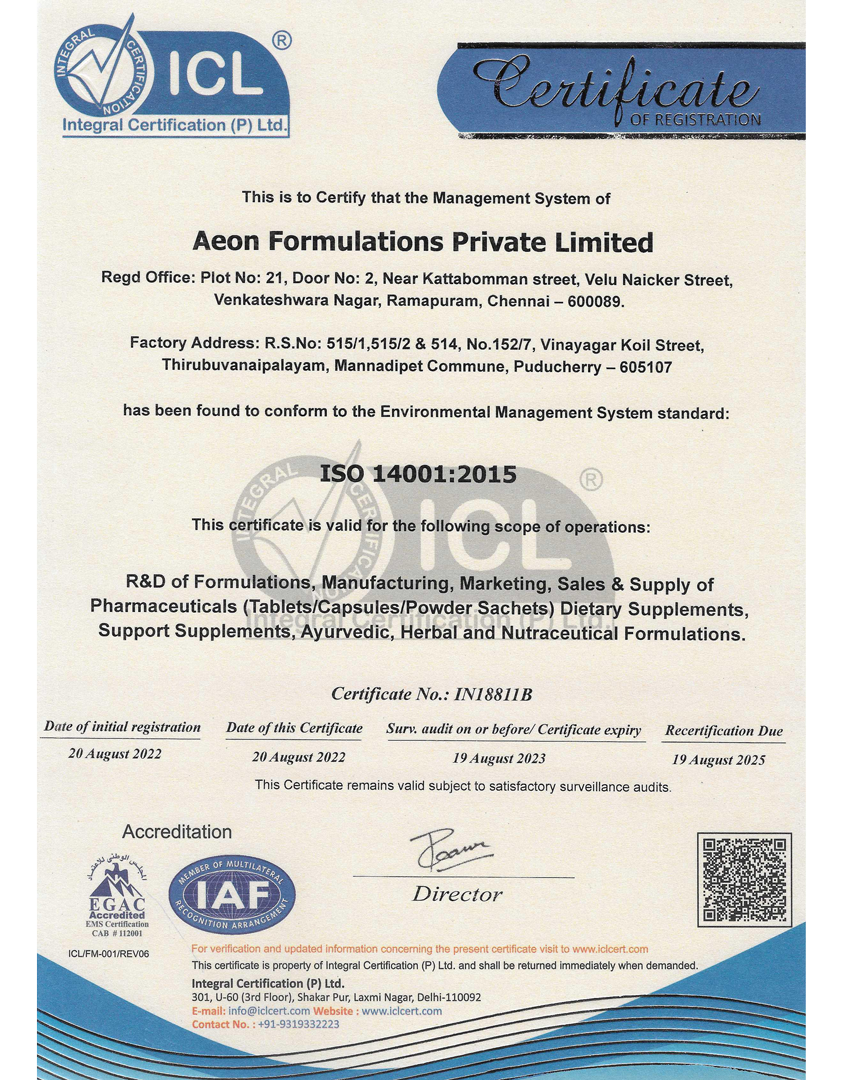

AWARDS

1. Award by M/S Burgeon Pharmaceuticals Pvt. Ltd.

2. Award by HYM International Certifications.

3. Bharat Gaurav Award.

4. 11th South East Ceo Conclave & Award 2019.

5. Award by The Global Trae Driver.

6. Awarded by Poultry India 2018.

7. Emerging Company Award.

8. Excellence in Nutraceutical & Ayush R&D of the year 2022

CLIENTELE:

Notable Clients and Partners:

We are proud to be contract manufacturers for leading organizations such as